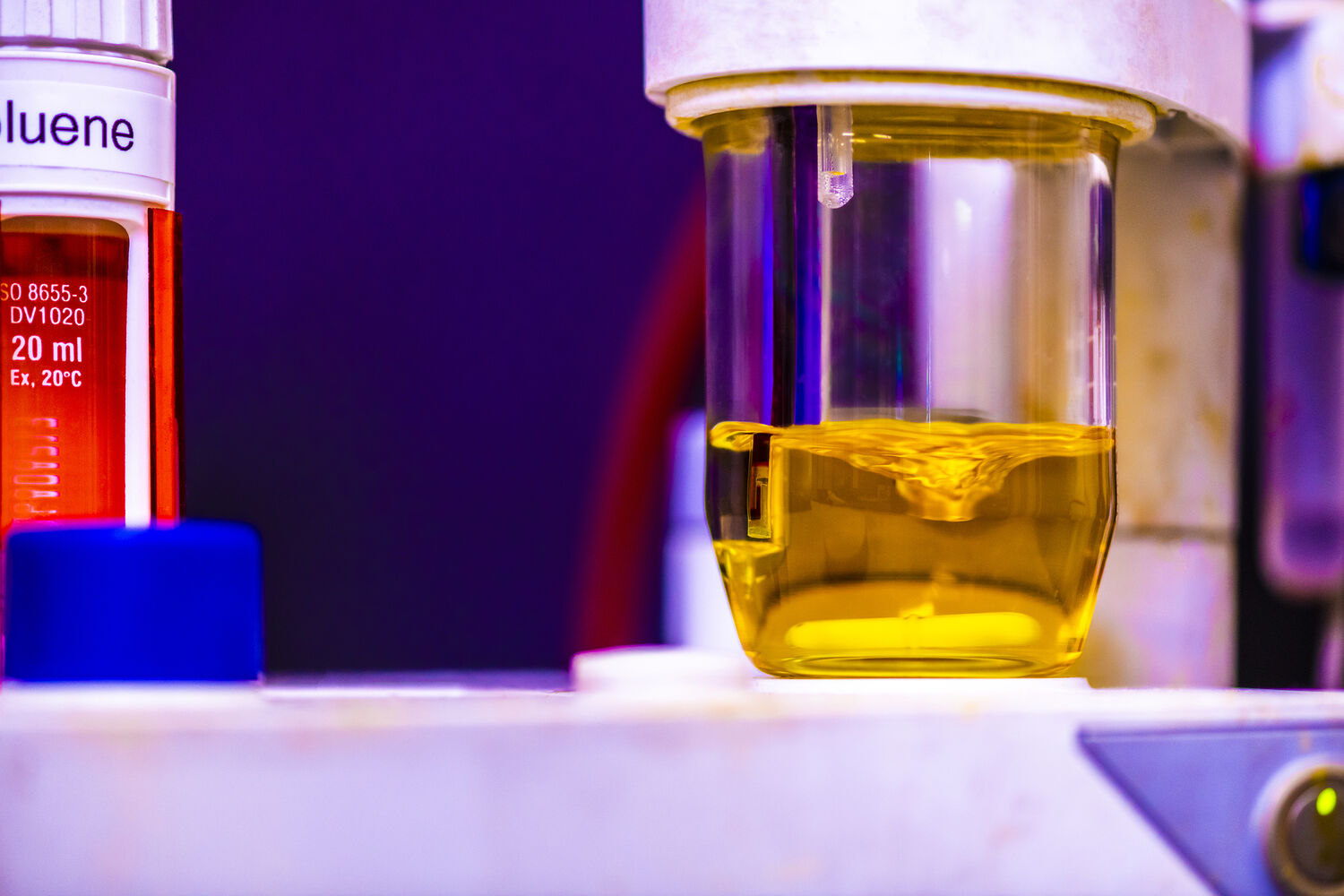

Core Formulation Expertise

Our team of skilled chemists and engineers combine decades of experience with cutting-edge analytical capabilities to develop solutions that meet the most demanding specifications.

Polyurethane Chemistry

Advanced formulation of polyurethane systems tailored to specific performance requirements.

- MDI-based systems

- Low-free monomer formulations

- Aromatic chemistries

- Moisture-cure and heat-cure systems

- Flexible to rigid hardness range

- Custom cure profiles and pot life

- Catalyst and additive optimisation

Adhesive Technology

Structural and semi-structural adhesives for demanding bonding applications.

- One and two-component systems

- Structural bonding adhesives

- Flexible sealant formulations

- Primer-less adhesion systems

- Multi-substrate compatibility

- Environmental resistance

- Rapid and controlled cure options

Hybrid Polymer Systems

Next-generation chemistry combining the benefits of multiple polymer technologies.

- Silane-terminated polymers (STP)

- MS polymer technology

- Epoxy-polyurethane systems

- Isocyanate-free formulations

- Paintable and non-paintable grades

Custom Pre-polymers

Bespoke reactive intermediates designed for specific customer applications.

- Controlled molecular weight distribution

- Functional end-capping options

- Viscosity and handling optimisation

- Stability and shelf-life enhancement

- Custom functionality incorporation

- Batch-to-batch consistency

- Scalable production processes

Repair & Maintenance

Specialised systems for structural repair and infrastructure maintenance.

- Crack injection systems

- Structural strengthening compounds

- Concrete bonding agents

- Protective coating systems

- Weathering and UV resistance

- Chemical resistance formulations

- Rapid setting emergency repairs

Sustainable Solutions

Environmentally responsible formulations without compromising performance.

- Low-VOC and VOC-free systems

- Bio-based raw material incorporation

- Recycled content formulations

- Solvent-free reactive systems

- Reduced environmental impact

- Circular economy principles

- REACH compliance assurance

Technical Capabilities

Quality & Standards

All formulations are developed and manufactured to the highest quality standards, ensuring consistency and reliability in every batch.

ISO 9001

Quality management system certification ensuring consistent product quality

REACH Compliance

Full regulatory compliance for European chemical legislation

Testing & Analysis

Comprehensive analytical capabilities for quality control and development

Confidentiality

Strict NDAs and IP protection for all customer projects

UK Manufacturing

All products manufactured at our West Yorkshire facility

Responsible Care

Member of the global chemical industry's commitment to sustainable development and continuous improvement